What is a hydraulic cylinder?

A hydraulic cylinder is a key hydraulic component. It serves as a hydraulic consumer that converts the energy of the hydraulic fluid into useful work. Its input value is the hydraulic fluid under pressure acting on the surface of the hydraulic cylinder piston. This causes a linear movement of the piston and thus the piston rod, which is connected to the load. Therefore, the energy of the hydraulic fluid is transformed into a controllable power, which acts in a straight line. The hydraulic medium is usually mineral oil, and in hydraulics, synthetic oils and emulsions, as well as water (water hydraulics), are also used.

Hydraulic cylinder components

Hydraulic cylinders are composed of two main elements, namely the barrel and the piston with an attached piston rod. The cylinder bottom and the cylinder head close both sides of the barrel respectively. The piston rod exits through the cylinder head. The piston, equipped with seals and sliding rings, divides the inside of the cylinder into two chambers, the lower pressure chamber and the upper piston rod chamber. The hydraulic pressure is generated by the piston that moves the piston rod in a linear direction. This type of cylinder is also called a double–acting hydraulic cylinder.

Description of the components:

Hydraulic cylinder barrel

The barrel is typically a seamless forged tube, which is ground and/or honed internally.

Hydraulic cylinder base

The base is welded or screwed to the cylinder barrel, although the base of some cylinders can be with or without a flange.

Hydraulic cylinder head

The head is typically attached with a screw connection, but can also be welded or attached to the barrel with a spring ring. The grooved inside of the cylinder head contains piston rod seals, a rod wiper and glands.

Hydraulic cylinder piston

The piston divides the cylinders into two chambers. The piston is sealed with a piston seal guided with guide rings, which prevents the passing of the oil between the chambers. The pressure difference between both chambers triggers cylinder movement.

Hydraulic cylinder piston rod

Piston rods are typically made from high–tolerance, hard chrome–plated cold–rolled steel. Piston rods are mounted onto the piston on one side and enter from the cylinder through the cylinder head on the other. An eye or flange is typically attached to the exterior side of the piston rod. Piston rods can be tempered, double chromed, hollow or stainless steel.

Welded port

These are used to supply the hydraulic fluid to and from the cylinder. Welded ports are available in inch and metric diameter values.

Cylinder seals

There are several types of cylinder seals. They vary according to their shape, material and installation method, as well as the operating temperature range and pressure of the hydraulic cylinder.

Rod end

The rod end is intended for connecting the cylinder to the load through the sliding bearing or bushes.

Self – locking nut

The self–locking nut is used for attaching the piston rod to the piston in certain types of applications.

Spring ring

It is used to limit the stroke of the plunger cylinder and to mount the cylinder head (with a spring ring).

Cylinder trunnion

For a pivotal installation of the cylinder.

Cylinder flange

It is used in flange connection.

Screw plug

Screw plugs protect the welded connections, and thus the interior of the cylinder, from impurities.

Bushes

Bushes are usually built into the welded rod ends of the cylinders. There are steel and self–lubricating bushes.

Sliding bearings

Sliding bearings are built into the cylinder heads that serve as a connection and attachment of the cylinder to the load.

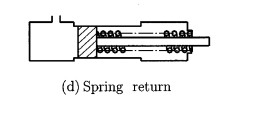

SINGLE ACTING HYDRAULIC CYLINDERS.

The characteristic of the single–acting piston hydraulic cylinder is that the operating stroke is only generated in a single direction; whereas, the return stroke is enabled by the load, spring or any other exterior force. Typically the working stroke can be generated as cylinder extraction, therefore this cylinder is a push cylinder; or the working stroke can be generated as cylinder contraction. This type of cylinder is called a pull cylinder.

DOUBLE ACTING HYDRAULIC CYLINDERS

Hydraulic cylinders with double acting operation (double-acting hydraulic cylinders) have two opposite facing piston surfaces that control the operation of the force of the hydraulic liquid, i.e. usually a special hydraulic oil that enables two active moving directions. The hydraulic energy is converted through the hydraulic liquid into the mechanical energy for the movement of the pistons. The pistons usually have separate connections that enable active movement in both directions. The force is thus applied in both directions and the structure of this hydraulic cylinder is very simple.

This type of cylinder with linear movement is especially suitable for use in presses and chippers, for opening and closing drawers and for all types of raising and lowering devices. The piston rod is attached to the piston in this structure. The piston can move faster if it has a smaller surface and slower if its surface is larger. This hydraulic cylinder is used for many types of construction machinery.

Hydraulic cylinders with double acting operation are divided into differential and synchronous types.

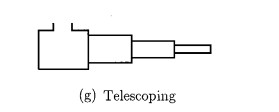

TELESCOPIC CYLINDERS

Telescopic cylinders or multi–stage cylinders are composed of a number of cylinders stacked on top of each other. Where the cylinder barrel also acts as a piston rod. Cylinders can have two, three, four, five or even six stages. They are most often used where the cylinder installation length is less than the required stroke. Most telescopic cylinders are single–acting, but there are also double–acting telescopic cylinders available.

Tandem cylinders are two interconnected cylinders. The piston rod of the first cylinder enters through the base of the second cylinder and pushes its base. In this manner the greater effective surface area of both pistons generates greater force, despite a small cylinder diameter and unaltered operating pressure.

Good Read. I know it is a vast subject and it would be difficult to manage the content in short. But , this one is an informative content. Similar to this here I would like to share an article that I found on Internet today types of hydraulic cylinder. Hope this is useful

LikeLike

I just wanted to thank you for helping me learn more about hydraulic cylinders. I actually didn’t about the double acting ones or that they can have connections to have movement in both directions. To be honest, I think it could be cool to be able to see these cylinders working in different operations, just to see what they are capable of.

LikeLike